In a power plant, it is essential to take control of dissolved oxygen (DO) to reduce corrosion levels and the resulting deposits of metal oxide corrosion in critical components. Measuring DO in power plants requires high-performing, reliable optical sensors to achieve successful management.

Strategies to Manage DO

Reducing and oxidizing are the two basic feedwater chemistry strategies used for managing DO in power plants.

Reducing conditions is the preferred strategy where copper alloys are in the feedwater. Technicians choose this strategy when they can’t maintain a high level of feedwater quality.

Oxidation is an option in situations where you have high-quality feedwater composed entirely of ferrous alloys.

Reduction is the right option when feedwater is poor quality and/or copper is detected. This strategy uses a combination of deaeration and a reducing agent such as hydrazine to lower the DO content. The result is a protective cuprous oxide layer over the copper alloy.

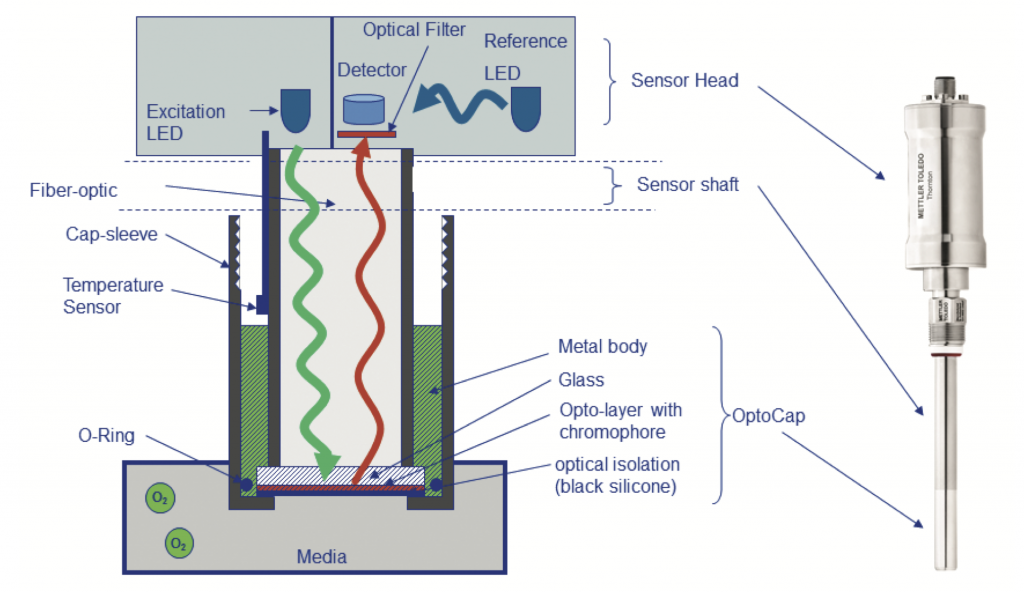

Optical Sensor Technology for PPB Levels

DO sensors use this method to calculate the exact amount of oxygen in the sample provided.