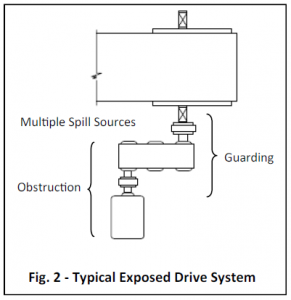

Conventional exposed conveyor drive systems typically include an external motor coupled to a gearbox or set of drive sheaves which in turn are connected to a drive pulley that act together to move a conveyor belt. To function well, this conventional system relies on the precise alignment and the proper maintenance and upkeep of multiple independent systems that often operate in wet, sandy, demanding environments.

Conventional exposed conveyor drive systems typically include an external motor coupled to a gearbox or set of drive sheaves which in turn are connected to a drive pulley that act together to move a conveyor belt. To function well, this conventional system relies on the precise alignment and the proper maintenance and upkeep of multiple independent systems that often operate in wet, sandy, demanding environments.

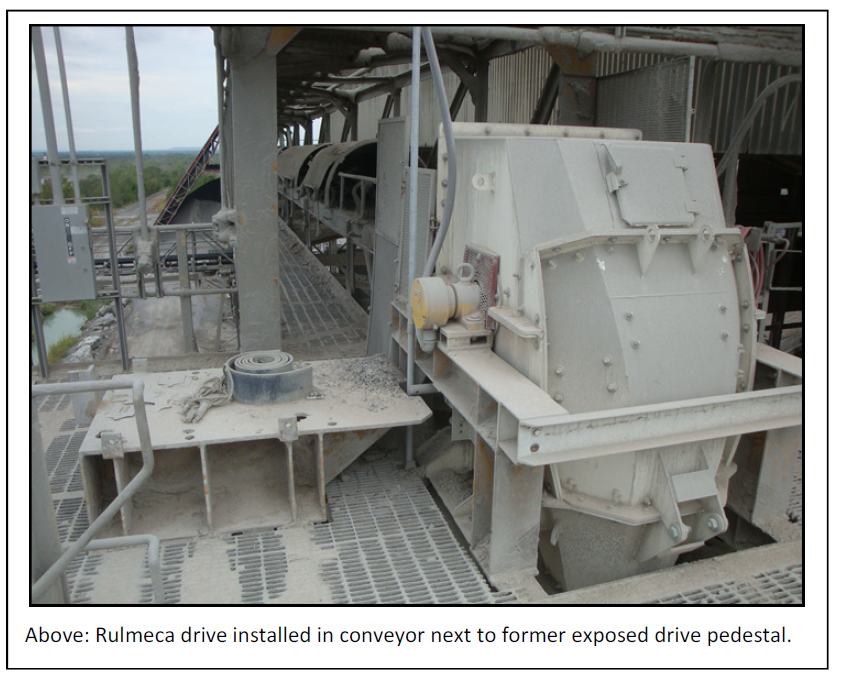

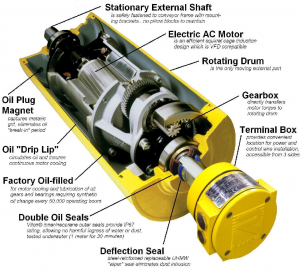

In contrast, Rulmeca motorized pulleys simplify the drive train and eliminate the externally interconnected components by elegantly locating the motor and speed transmission within the drive pulley shell itself. Many advantages come along with this elegant solution including decreased conveyor downtime, reduced maintenance expense, less space required around the conveyor headworks, lower electrical power consumption, and improved safety. Additionally, Rulmeca motorized pulleys have been used to solve conveyor specific problems including belt slapping, belt slipping, and poor belt training.

Rulmeca motorized pulleys can be provided to match most conveyor installation requirements. A wide variety of operating conditions can be met by matching the appropriate pulley diameter, drive horsepower, belt speed, and lagging type.

Ready to learn more – contact Jasper Engineering today to learn more about how Rulmeca Motorized Pulleys can increase the reliability, safety, and efficiency of your operation at (218) 262-342 or (952) 938-6504, or email us at sales@jaspereng.com.