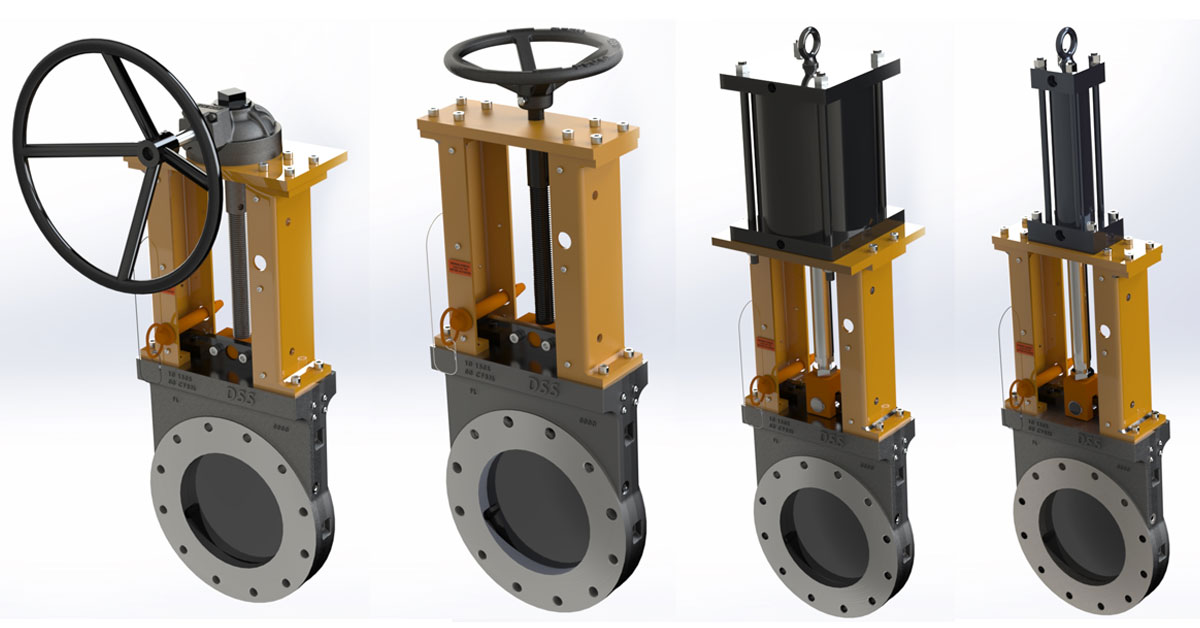

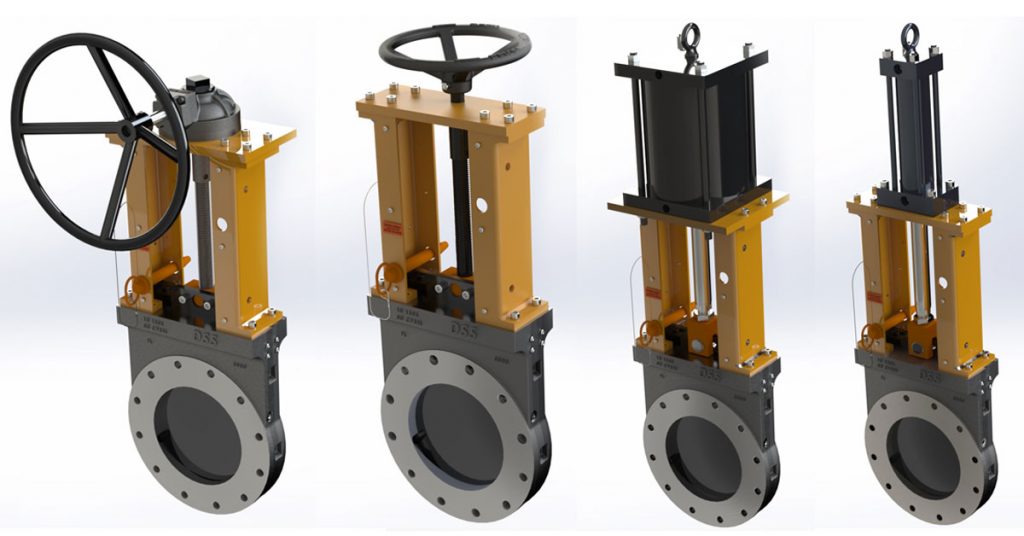

Watch this short introduction of the DSS Severe Service Knife Gate Valve (SSKVG)

Play Video

We provide customers with experienced, technical advice for engineered applications including:

The company was founded in 1958 in Hibbing, Minnesota, to serve the needs of the mining industry, but today is known throughout the Upper Midwest as a problem-solver for multiple industries with an emphasis on process industries.

Jasper’s team of experienced product managers provides their customers with top quality products that solve their customers’ urgent needs.

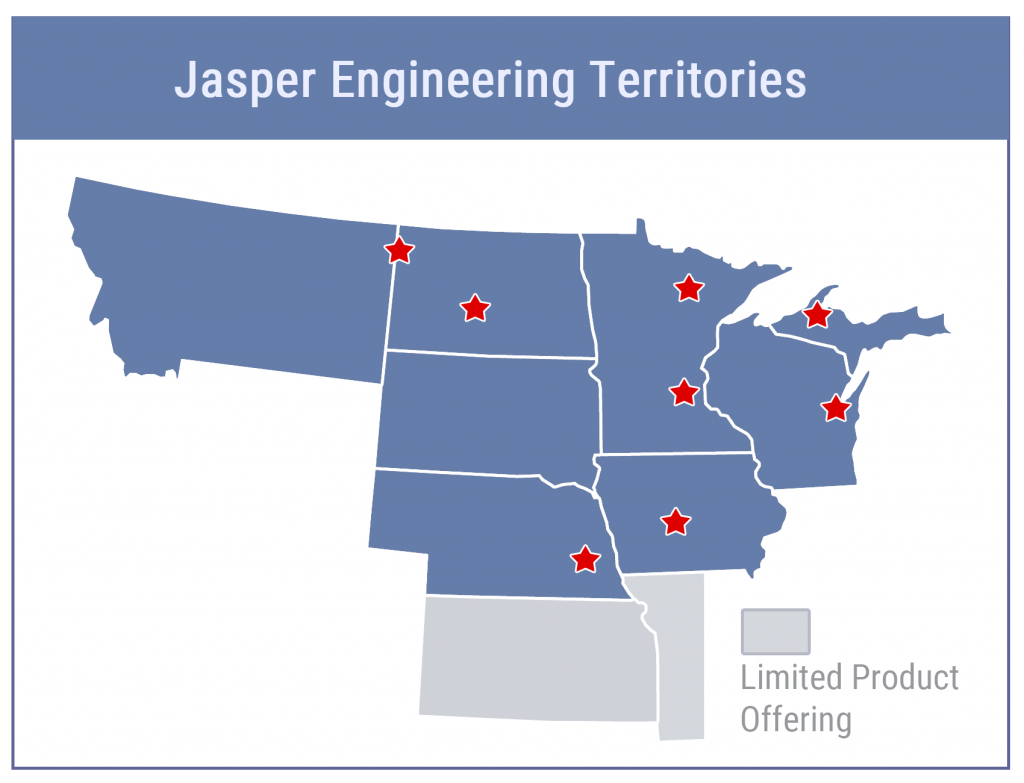

With seven locations serving 10 states and 50 employees, there’s a Jasper representative nearby and ready to answer questions, develop solutions, and connect customers to trustworthy products and brands.

Not ready to talk with our representatives but want to explore more information? Download the Product Brochure to get a more detailed look into features, benefits, and design specs.

Jasper Engineering represents DSS Valves in the Upper Midwest.

Contact us today to learn more.

Call (800) 776-6184 or 952-938-6504

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |