If you are like me, you started your adventure into process measurement with measuring liquid and gas flows, temperatures, and pressures. I got very good at designing systems using the proper instrumentation to measure and control these. However, I didn’t pay much attention to solids measurement. This has since changed. I work with solids control in a large percentage of my projects now. I have come to realize that the expertise gained in liquid control does not always directly translate to solids measurement.

There are 5 main ways to measure solids flow. They are as follows:

- Belt speed measurement

- Conveyor motor amp draw

- Belt Scale Conveyor

- Impact Mass Flow

- Radiometric Absorption Conveyor

Belt speed measurement is the simplest method, but it is also the most inaccurate. This method just measures the linear speed of your conveyor or screw and estimates the mass of the dry product it conveys per minute. Sometimes this is okay, but it assumes a steady feed rate and steady product density. This method shouldn’t be used for control or inventory tracking.

Conveyor motor amp draw measurement assumes that increased amps is an increase in mass being conveyed. This is a better idea than purely monitoring the conveyor’s speed, but it too has massive drawbacks. It assumes that the conveyor itself is steady state mechanically. Does your conveyor have a consistent friction at all speeds and temperatures? Probably not. Do mechanical systems wear over time causing “calibration” drift? Probably. Does the amp increase vary linearly with mass increase? Probably not. I personally don’t like these systems as they don’t work very well and give a false sense of having measured something well, when in fact you have not.

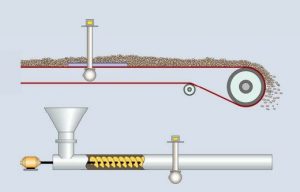

Belt scale conveyors are the gold standard in mass flow accuracy. They consist of load cells on independently supported rollers under a conveyor belt. There can be from one to 4 of these roller/load cells in series. As solid product rolls over these load cells, it is weighed. This weight and an output from a speed sensor combine to give you an extremely accurate mass flow. These systems, depending on the number of load cells, can give a mass flow reading of up to +/-0.25%. These systems aren’t very expensive in the scheme of things, but they do require a lot of straight space in your belt to install and work properly. They also rely on moving parts and are exposed to the dust from the solids which will require maintenance and periodic recalibration with provided reference weights. Overall, these are the most accurate systems you can get.

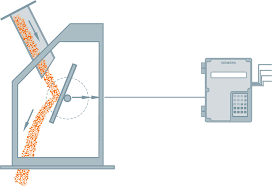

Impact mass flowmeters are the next most accurate solids flow measurement device. These require that product be lifted above this “box” and dropped through it down to a bin or secondary conveyor. This “box” consists of a top entry chute and a bottom outlet chute. In the middle of this box is an angled plate attached to a load cell. As solids fall into the box, they strike the load cell plate and then fall off and out of the box. The load cell sensor assembly is sensitive enough to track the rate and mass of the solids going through it and gives you a reliable +/-0.75 to 1.00 percent accuracy spec. These require less maintenance than the belt scales, but still need cleaned periodically as the sensor is exposed to dust and the plate is open to wear from the impact of potentially abrasive solids. These are a great option if you have the vertical space to fit it into your process.

Lastly is relatively unknown method of radiometric absorption. This method uses a radio isotope to emit gamma rays at a known and regular rate. The conveyor and the material being conveyed absorb these gamma rays. The conveyor never changes density, so it absorbs the same amount of gamma all the time. The change in absorption over time is therefore directly related to the change in product mass flow. The levels of gamma rays emitted are so low as to make these safe for install in the field. In fact, (only with Ronan) no special certificate or government regulation applies to most of their installs. These systems do not make contact with the product and are installed outside of the conveyor. This means they require no maintenance as dust and abrasion are not a factor. They have a pretty good accuracy rating of +/-1-2% in most applications.

Now that you know the main ways to measure solids mass flow, it’s time to include this in your plant’s mass balance calculations and inventory controls if you haven’t already. If you have questions about how to implement this in your process or how to correct an install this isn’t living up to your expectations please contact Jasper Engineering today at (218) 262-342 or (952) 938-6504, or email us at sales@jaspereng.com.