Many of the commercial and industrial processes that support the basic necessities of daily life – including power generation, steel and road making, and food production rely on stockpiling raw materials. These stockpiles of coal, sand, gravel, taconite, sugar beets, and wood pulp can be thousands of tons of material covering a large foot-print and extending to significant height. In strong winds,the smallest particles of the material on the stockpile can be lifted from the pile and become airborne only to be deposited where and when nature wills. When stockpiles are located in areas of high population density, too often the final resting place of the dust particle is somewhere less than desirable including on homes, cars, and businesses.

Fortunately, an engineered solution exists to reduce and eliminate the ability of wind to generate this dust – a wind fence.

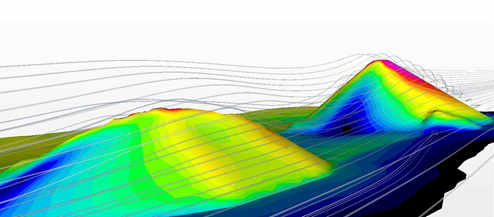

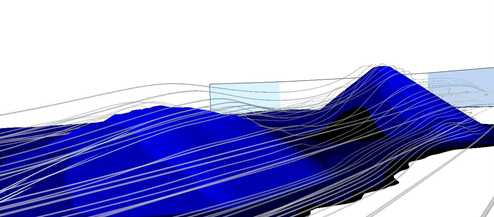

A wind fence consists of a semi-permeable fabric supported between piers and located on the up-wind side of the stockpile. The fabric reduces the velocity of the wind below the velocity required to lift dust from the pile and make it airborne. The models below show the effect of adding a wind fence upstream of the two stockpiles. In the second image, with the wind fence, the wind velocity has been reduced (as indicated by the blue color) and dust will not be lifted from the stockpile.

Wind fences are a highly effective and low maintenance solution to reducing nuisance dust generation. Please contact Jasper Engineering today to learn more about how wind fences can help eliminate your nuisance dust problems.