In any manufacturing plant, routine maintenance is critical to ensuring the smooth operation of the equipment. This is especially important in pulp and paper mills where the liquors used (white, black, and green) as well as heat and pressure can cause scale, buildup, and corrosion of pipes and valves.

Routine maintenance such as flushing valves and checking seals can become problematic in tight spaces. Maintenance workers often note that changing out a valve can be extremely challenging in confined spaces when overly large valves must be moved in and out.

Jasper Engineering Recommends DSS Valves

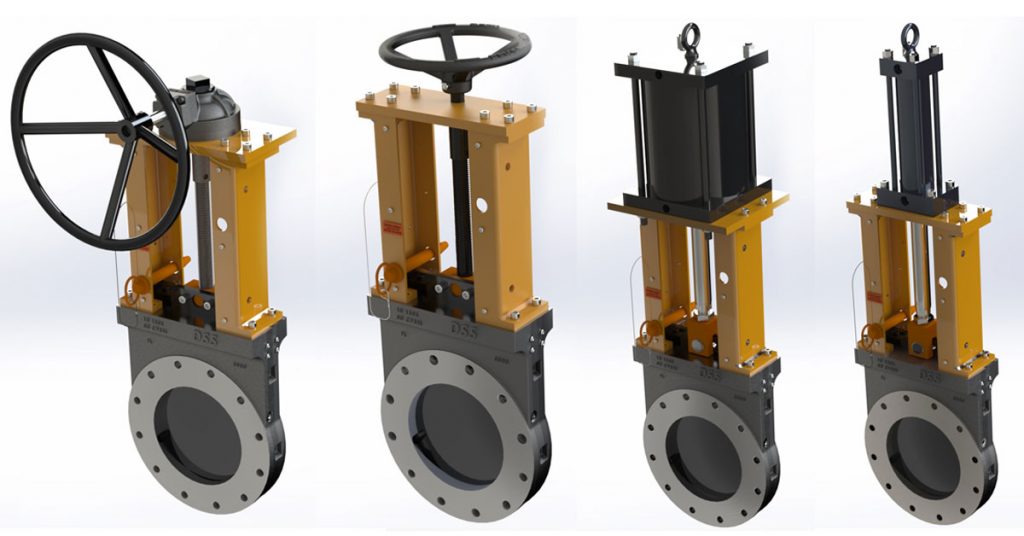

Fortunately, DSS Valves offers an excellent solution in their Severe Service Knife Gate Valve. Jasper Engineering recommends these valves to our customers in the pulp and paper industry for many reasons:

- The fully guided gate ensures the gate is always in contact with the seat, providing zero-leakage isolation

- All valves are tested at the factory to be zero leakage in both high and low pressures

- Dual transverse seal ensures containment within the pipeline with no leakage

- Visible lockout pin which is easy to see when valve is completely closed and locked

- Shears through solids

- Smaller footprint compared to plug or ball valves

DSS Valves are made to withstand high temperatures, high pressures, chemicals, and solids often found in pulp and paper mills. All DSS Valves (with the exception of the M81) come standard with full aSME pressure ratings.

These and other features make DSS Valves an excellent addition to any pulp or paper mill. We invite plant and mill owners to contact Jasper Engineering for a thorough review of your plant’s needs. We can recommend products to help you improve plant safety and add to the longevity of your equipment.